Get the most out of your learning with our

ACCESS-ALL SUBSCRIPTION

Subscribe to access all streamed video lessons

£18.99 per month

£18.99 per month

Floating and Flattening the Zombie Makeup

Neill Gorton

Floating and Flattening the Zombie MakeupDividing up the prosthetic sculpture into smaller pieces that will then recombine to create the finished character makeup. Where to make the joins and planning the overlaps. Once floated how to flatten and finish detailing the sculptures.

Floating the Sculpture and Preparing for Snap Moulds

Neill Gorton

Floating the Sculpture and Preparing for Snap MouldsA plastiline sculpture of a prosthetic makeup that has been done on a plaster cast prepared with a water-soluble separator will need to be “floated off” in order to prepare it for final moulding. Here we show the steps of both floating off and of preparing some of the sculptures for taking snap moulds which enable us to create overlapping appliances.Making a Brush-Up Silicone Mould of a Life Cast

Neill Gorton

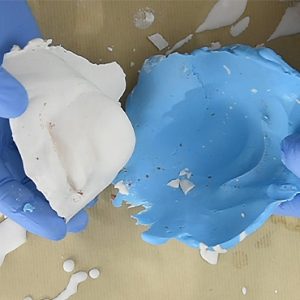

Making a Brush Up Silicone Mould of a Life CastThe process of mounting and extending a life cast in preparation for moulding and then moulding it using the silicone brush on method. This silicone mould is then supported with a plaster jacket.

Making Flat Moulds Using Plaster

Neill Gorton

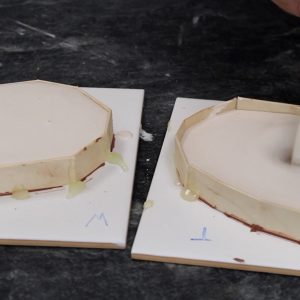

Making Flat Moulds Using PlasterThe flat mould making process in its most basic form using plaster as a mould making medium.

Mould Making Part One: Cheeks and Forehead

Neill Gorton

Mould Making Part One: Cheeks and Forehead Creating new cores to transfer the floated forehead and cheek appliance sculptures on to. We cast a rigid foam copy from the silicone negative mould and use this to help define the best shape and make a guide for producing plaster copies.

Mould Making Part One: Chin, Lips and Nose

Neill Gorton

Mould Making Part One: Chin, Lips and NoseCreating new cores to transfer the floated chin, lips and nose appliance sculptures to. We create snap moulds in alginate and cast plaster copies from these which are shaped in readiness for moulding in silicone and casting positives in PU resin.

Mould Making Part Three: Cheeks

Neill Gorton

Mould Making Part Three: Cheeks Casting the cheek cores in polyurethane resin and using fillers.