Get the most out of your learning with our

ACCESS-ALL SUBSCRIPTION

Subscribe to access all streamed video lessons

£18.99 per month

£18.99 per month

Matrix Moulding the Cyclops – Part Two

Neill Gorton

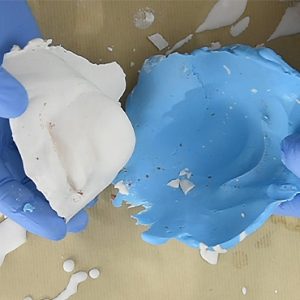

Matrix Moulding the Cyclops Part TwoMatrix moulding from a WED clay sculpture. Matrix moulds provide a way of creating a more controlled thickness of silicone over the sculpture when making your mould. The process of making a matrix mould is slightly more involved than that of a brush-up mould but yields more superior and reliable results.

Mould Making Part One: Cheeks and Forehead

Neill Gorton

Mould Making Part One: Cheeks and Forehead Creating new cores to transfer the floated forehead and cheek appliance sculptures on to. We cast a rigid foam copy from the silicone negative mould and use this to help define the best shape and make a guide for producing plaster copies.

Mould Making Part One: Chin, Lips and Nose

Neill Gorton

Mould Making Part One: Chin, Lips and NoseCreating new cores to transfer the floated chin, lips and nose appliance sculptures to. We create snap moulds in alginate and cast plaster copies from these which are shaped in readiness for moulding in silicone and casting positives in PU resin.

Mould Making Part Three: Cheeks

Neill Gorton

Mould Making Part Three: Cheeks Casting the cheek cores in polyurethane resin and using fillers.

Mould Making Part Three: Chin, Lips and Nose

Neill Gorton

Mould Making Part Three: Chin, Lips and NoseCasting the chin, nose and lip cores in a hard polyurethane casting resin.

Mould Making Part Three: Forehead

Neill Gorton

Mould Making Part Three: ForeheadCasting the forehead in a hard polyurethane casting back filled with a fast cast resin and filler. Inserting bolts to create screw threads for mould opening.

Mould Making Part Two: Cheeks

Neill Gorton

Mould Making Part Two: CheeksBlock moulding the cheek cores in silicone and casting them out in polyurethane resin.